Good Quality 1500kg/h Automation Food Grade B2B PET Bottle Washing Line

Product Description:

The food grade B2B PET bottle washing line includes a whole set of B2B Recycling Machines which make PET bottle into PET flakes up to the food grade.The convert process as following:

Bales are feed into the bale breaker machine which broke the bale,and loose the bottles so as to prepare them for further decontamination process.

Bottle sorter has a function of sorting the non PET bottles and making sure the bottles are in align with food grade standards so as to enter the plastic crusher machineand the PET bottle washing line.

Hot washing tank is responsible for washing the flakes.It removes the impurity and glue on PET bottle surface, make sure PET flakes without impurity.

The PET bottle washing recycling line configures 4-5 floating tank and 2-3 high speed friction washing machine,make sure the PET flakes clean , up to B2B grade.2-3 zigzag separator for separating the pvc and labels, the pvc ratio of PET flakes less than 30ppm.

PET flakes color sorter and polymer sorter,aging sorter seperate non PET flakes from non PET flakes, and get white color PET flakes.

Eddy current separator is responsible for seperating metal and nonferrous metal, aluminium etc from the PET flakes before packing.Before packing,continuous monitoring and testing is done to ensure only outputing quality flakes which are up to food grade,then Packing them in jumbo bags automatically.

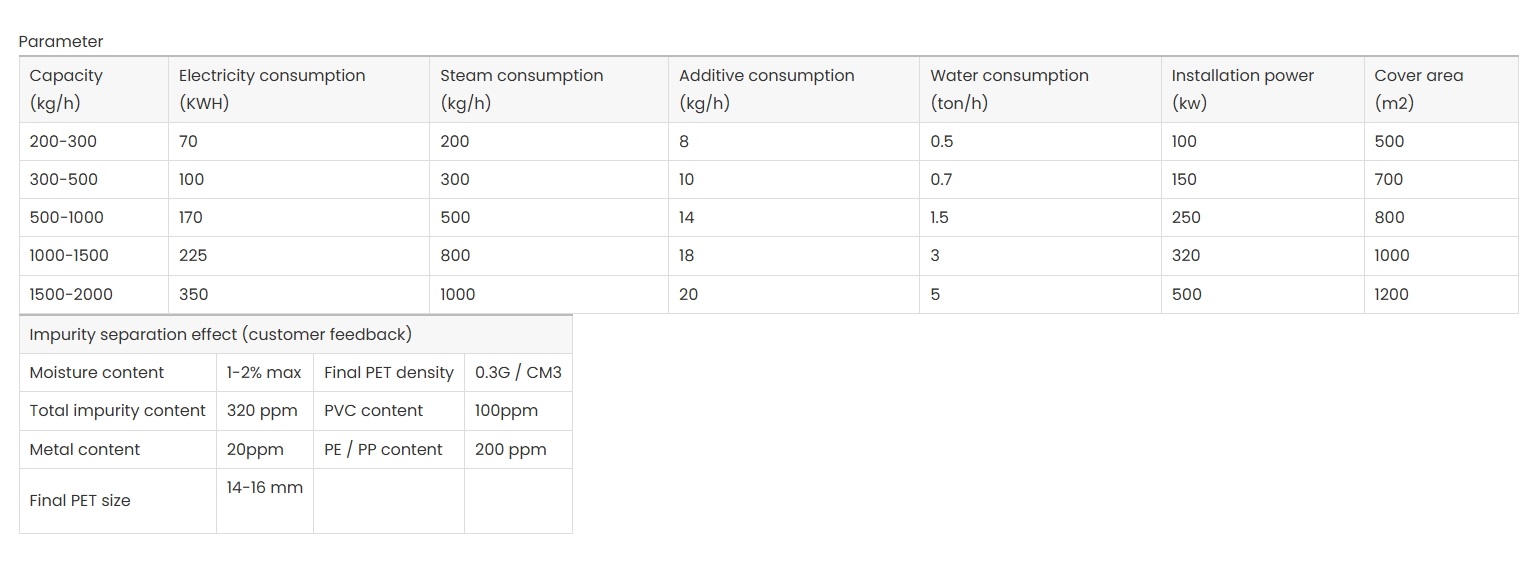

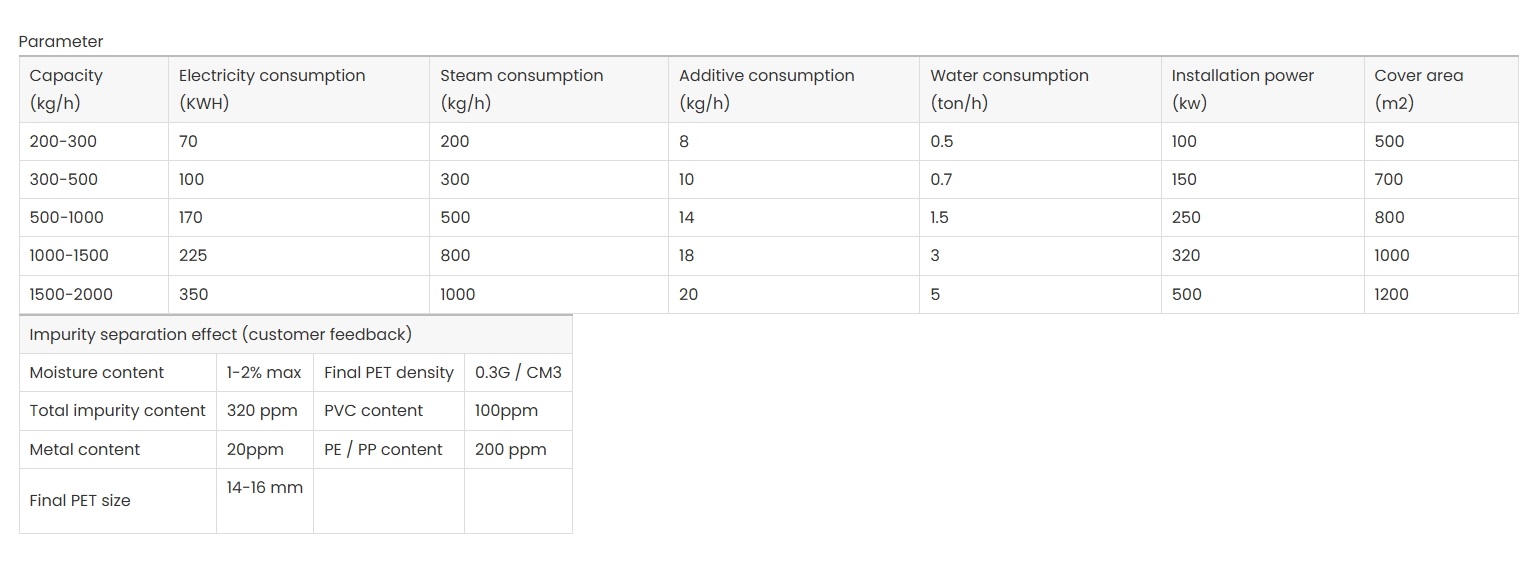

Product Parameters:

food grade pet bottle washing recycling line

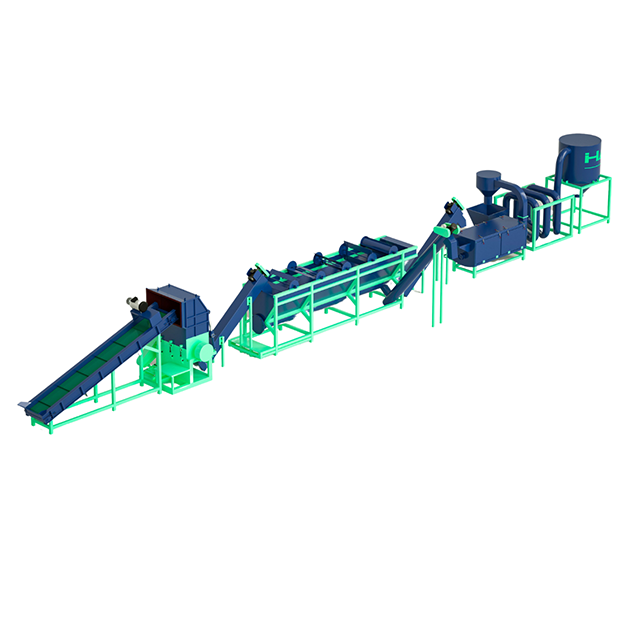

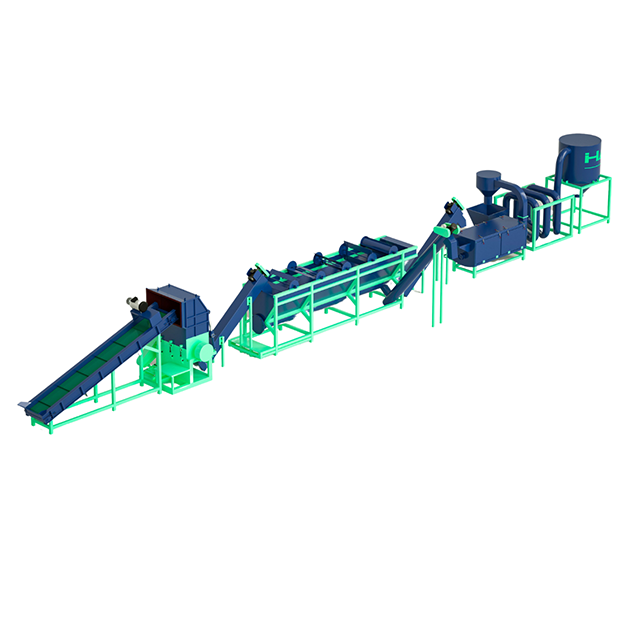

Product Display:

pet bottle washing line