High Automation 300kg/hr PET Sheet PET Bottle Recycling Machine for Plastic Washing Line

Product Description:

Multiple function:Sheet & bottle cleaning system is resposible for processing a wide range of plastic materials with various levels of contamination including extremely heavy contamination such as oil based substances and agricultural wastes.

Wide usage:The PET bottle washing recycling line is widely used for recycling PE PP bag, woven bag, non-woven bag, HDPE milk bottle, oil barrel, oil tank, basket, agricultural film etc. The final product can be used for granulation, blow molding and injection.

Key features:The whole PET bottle recycling line is easy to operate, high automation and low energy consumption.

Various products:Our company can provide a wide range of standard and customized sheet & bottle cleaning system to meet the different requirements of a modern recycling environment. There are 200-15000kg/h capacities , we need your detailed requirements to make quotations according to.

PET bottle washing recycling line typically includes the following machines:

• Belt conveyor:Transports waste material for infeeding.

• Metal Detector:detects metal contamination that may remain in the bottles.

• Plastic crusher machine: It refers to a wet crushing system.It used for reducting material size and pre-washing material by water spraying from the top.

• Screw conveyor : It responsible for transporting PP PE flakes.

• High speed friction washer: This machine could achieve a good cleaning effects through the combined blades that are made of SKD-11 tool steel and get a patent on the beating and rub.

• Hot washing tank/ Steam washer:The hot washing process is with alkaline (caustic) soda to remove glue and oil.

• Washing tank/ Float washer: It is resposible for floating washing and conveying flakes.

• Horizontal dewatering machine( Dehydrator):This machine is mainly used for drying the pp pe flakes .It throws the water out from the screen by high speed rotating ,the plastic gets out of the machine and enters the next procedure from the outlet.The machine has a good drying effect and high efficiency. The paddle is made of high wear-resistant materials.It is more convenient to be replaced.

• Hot air dryer:This machine can dry the pet flakes further by hot air.

• Blower and transition silo:The output is blowed and transportated to storage silo.

• Control cabinet: It is responsible for controlling the whole sheet & bottle cleaning system intensively.

Product Features:

1.Main material contact with water adopts stainless steel 304.

2.Complete solution for PET sheet & bottle washing line installation,water circulation and operation training.

3.Output capacities: Capacities include 200kg/h,300kg/h,500kg/h,1000kg/h,1500kg/h.They are optional from 200kg per hour to 1500kg per hour.

4. Negotiable washing process to help customer get the most suitable washing line.

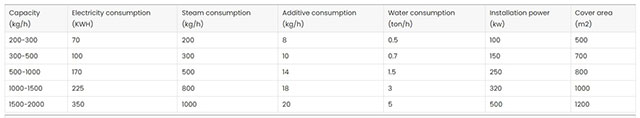

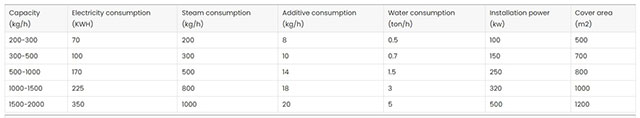

Product Parameters:

PET bottle recycling machine

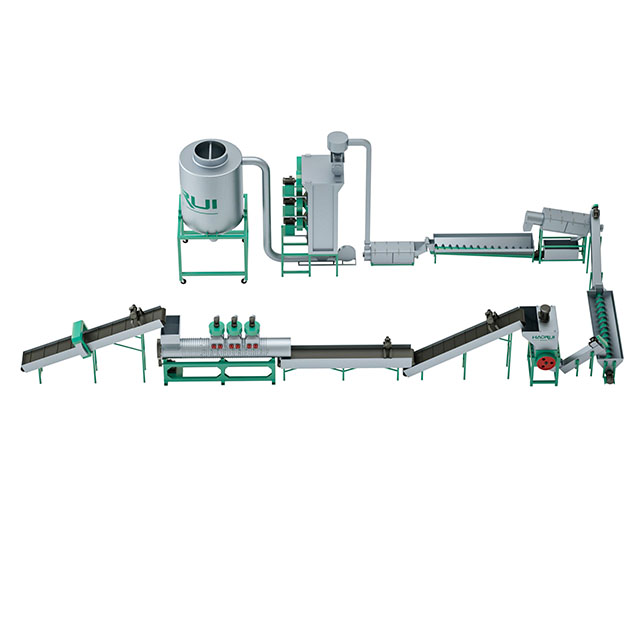

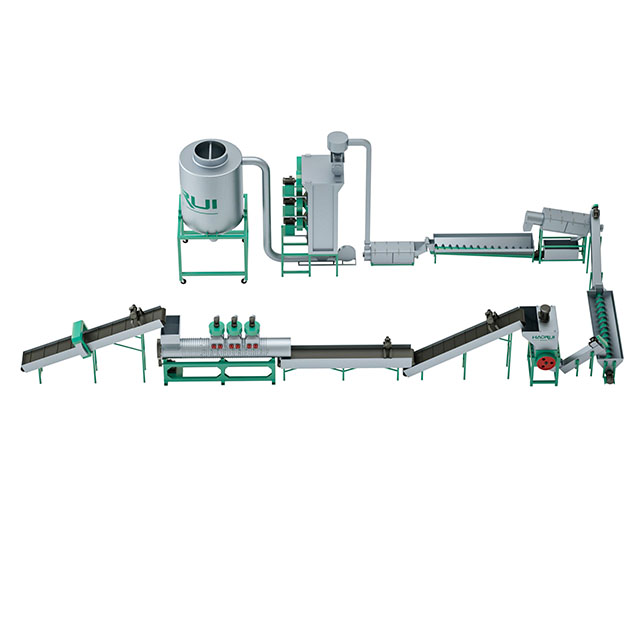

Product Display:

plastic recycling washing line