Key Attributes of Plastic Recycle Washing Line

Weight (T):20

Warranty:1 Year

Showroom Location:Nigeria

-

Production Capacity (kg/h):1000-1500

Voltage:380v/Custom

-

Material of blades:SKD-11/D2

Delivery of Plastic Recycle Washing Line

All production and manufacturing are completed in ourfactory, and we can effectively control quality and delivery time

Lead time (days):25 To be negotiated

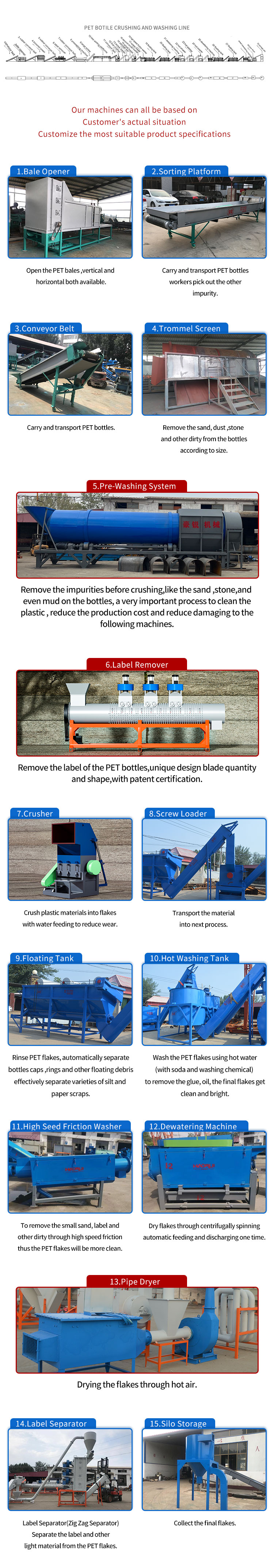

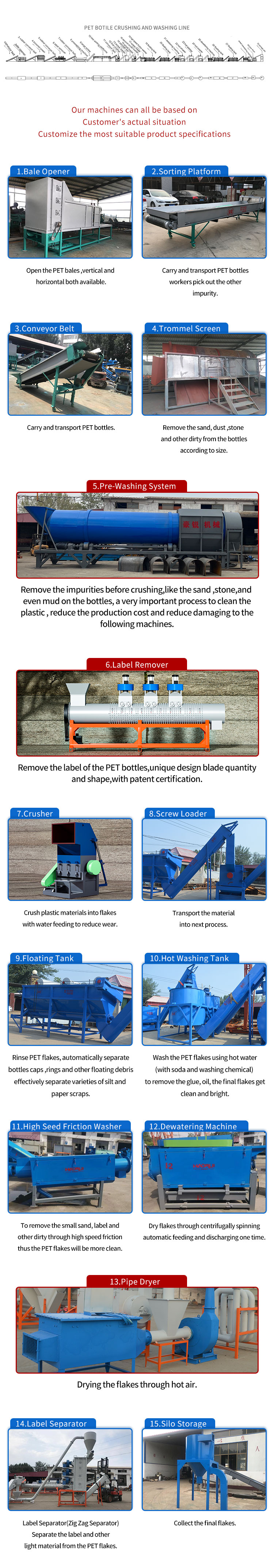

Product Despriction of Plastic Recycle Washing Line

Label remover

Usage: remove the pvc labels of the PET bottles

1. knife material:alloy

2. Capacity:1000kg/h

3. Shafts:single shaft

4. Spare parts:motor,fan, V-belt ,protective cover

Plastic crusher

Usage: To crush PET bottle with water into flakes.

1. Capacity:1000kg/h

2. Type:1000type

3. The cover opening method: hydraulic elevator

4. Blade material:SKD-11

5. Material:carbon steel / 304SS

6. Bearing: Chinese famous brand (HRB brand)

Floating tank

Usage:rinse PET flakes, automatically separate bottles caps and other floating debris ,effectively separate varieties of silt and paper scraps With three push rollers and a small screw conveyor for the PP PE caps

1. Material: carbon steel

2. Number of roller wheels:4pcs

3. Number of bottom worm shaft:1 pc

Dewatering machine

Usage: Dry flakes through centrifugally spinning,automatic feeding and discharging the flakes

1. Whole screen type dewatering machine

2. Type: Horizontal

3. Discharge the PET flakes from side, drain water from bottom

4. Mesh material: 304 stainless steel

5. Helical blades material:carbon steel

6. Bearing: ZWZ bearing( Chinese famous brand)

Mode of Payment of Plastic Recycle Washing Line

L/C,D/A,D/P,T/T,Western Union,MoneyGram

After-Sales Service of Plastic Recycle Washing Line

One year remote warranty

Dispatched engineers are responsible for product installation and maintenance

Provide local after-sales service

Thirteen Patents and Certifications of Plastic Recycle Washing Line

Company Profile of Plastic Recycle Washing Line

HAORUl Machinery was established in 1992,aprofessional manufacturer & exporter of PET bottlerecycling machine, PP PE plastic bag / film /bottlerecycling machine, pelletizing machine etc.

We already helped over 40 clients solve the plasticrecycling investment solution in Vietnam, Thailand,Laos, Cambodia,Myanmar, India, Saudi Arabia, USA.Nigeria, Ghana, Kenya, Algeria, South Africa, Turkeyetc.

We have over 300 employees, an annual salesfigure that exceeds USD10million dollars and arecurrently exporting30% of our production.

Always insist on “quality is first””and inspect afterproducing which makes us more popular in Domesticand gained a global sales network all over theworld.

There are over 100 technicians in our workshopswhich covers 20000m2.0ver 30 years experience andour9 persons’R&D team make our machine designunique, OEM &ODM are welcome

Customer Photos of Plastic Recycle Washing Line

FAQ of Plastic Recycle Washing Line

Q: How often are the Crusher blades sharpened?

A: After continuous working at 30-40hours, the blades have to be sharpened

Q: How long does it take for changing blades—Remove and install blades?

A: Depending on the worker skilled or not. Normally 2-3hours

Q: How about the rate for removing the labels by Label remover?

A: Compressed bottle: more than 96%

Un-compressed bottle: more than 98%

Q:What’s the temperature of steam washer ?

A: Usually 80-90℃ ( If the temperature is over 100℃, the Flake will be roll.so the best temperature

is 80-90℃)

Q: What’s the moisture after Horizontal dewatering machine?

A: About 1.8%. Adopt Swedeen SKF bearing, with bearing layer on the surface of screw blades

for longer working life.

Q: How often are the Crusher blades sharpened?

A: After continuous working at 30-40hours, the blades have to be sharpened

Q: How long does it take for changing blades—Remove and install blades?

A: Depending on the worker skilled or not. Normally 2-3hours