Plastic Recycling Equipment Pet Bottle PP PE Plastic Pelletizing Machine

The pet bottle PP PE plastic granulator is a device specifically designed for recycling and regenerating plastics such as PP, PE, PET, and producing mixed color granulation. It adopts a special screw design and different configurations to meet the processing needs of different plastic materials. The gearbox of the plastic granulator adopts a high torque design to ensure smooth and noise free operation of the equipment. The screw and cylinder have undergone special hardening treatment, possessing excellent wear resistance, stirring performance, and high production capacity.

In order to ensure product quality, the plastic recycling granulator machine adopts the design of vacuum exhaust or ordinary exhaust port, which can effectively eliminate moisture and exhaust gas during the production process, making the material more stable. In addition, the setting of exhaust also helps to improve the firmness of rubber particles, thereby ensuring good quality of the final product.

By using plastic recycling equipment such as pet bottles PP PE plastic granulators, waste plastic resources such as pet bottles can be fully utilized for reuse and regeneration. By processing plastic fragments and processing them through a plastic granulator, high-quality plastic particles can be obtained, providing raw materials for the production of new plastic products. This not only helps reduce the impact of plastic waste on the environment, but also saves resources and achieves sustainable development.

Therefore, the PET reprocessing equipment plays an important role in the plastic recycling industry. Its special screw design, high torque gearbox, specially hardened screws and cylinder, as well as exhaust port settings, make it perform well in handling different types of plastics. The use of this device not only improves the efficiency of plastic recycling and reuse, but also promotes the achievement of sustainable development goals.

Product Features:

1. The heating system consists of heating rings distributed outside the cylinder. The heating ring can evenly distribute and heat the materials inside the cylinder, while the set temperature changes are automatically adjusted through instruments on the electrical control cabinet.

2. The barrel of the machine is designed with 45 steel that has undergone precision machining and quenching treatment, possessing excellent hardness, wear resistance, and corrosion resistance. In addition, for the convenience of feeding, a certain size of groove is specially set at the feeding end.

3. To ensure the stability of the temperature inside the cylinder, the designer added a cooling fan at the bottom of the cylinder. When the temperature exceeds the set value, the cooling fan will automatically start, thereby improving the temperature stability of the gun barrel.

4. After being cooled by the cooling system, the strip enters the granulator and is rolled and cut into granules for packaging. The granulator is equipped with a rolling feed wheel, which is driven by a motor to automatically transport materials to the main body. The rolling blades inside the main body are responsible for cutting the materials.

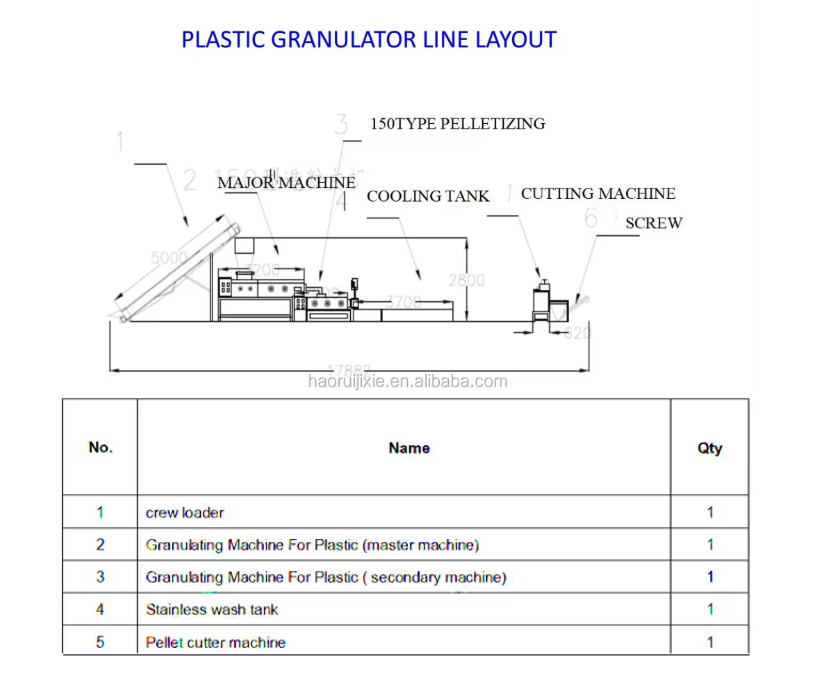

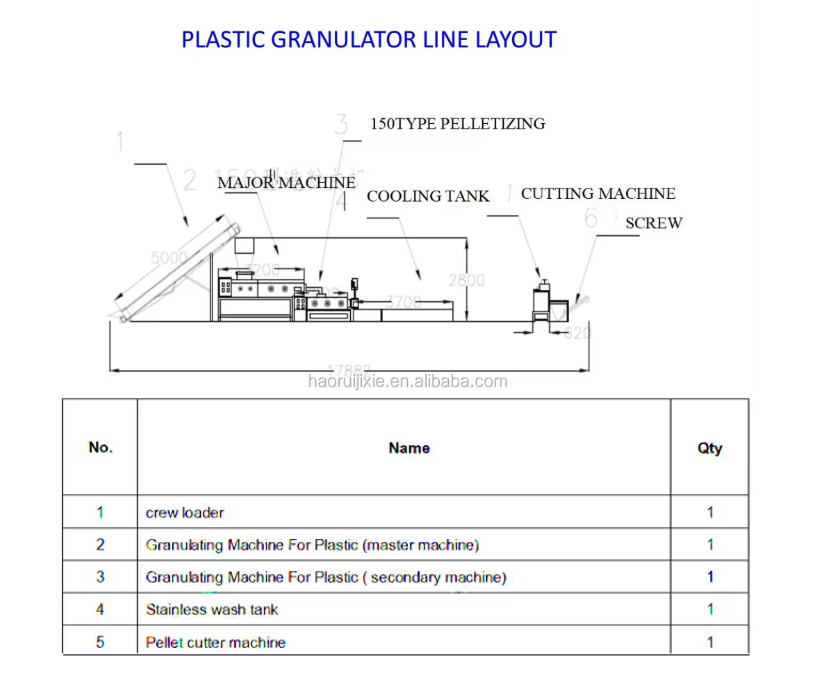

Product Layout:

PET Granulator Line

Our Advantages:

PET Granulating Machine