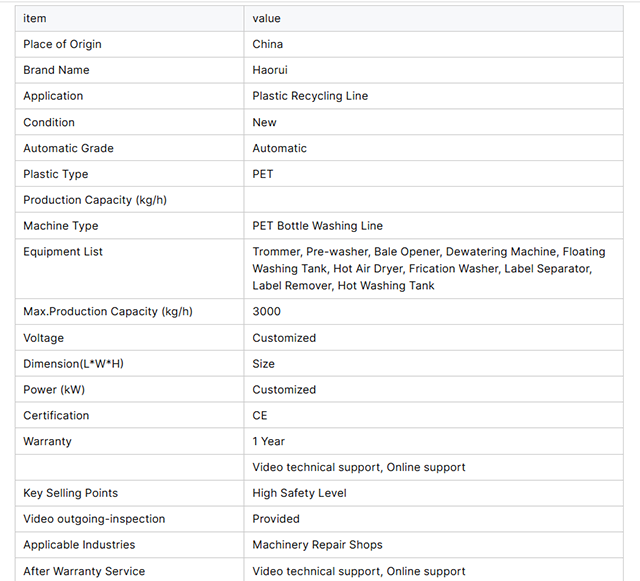

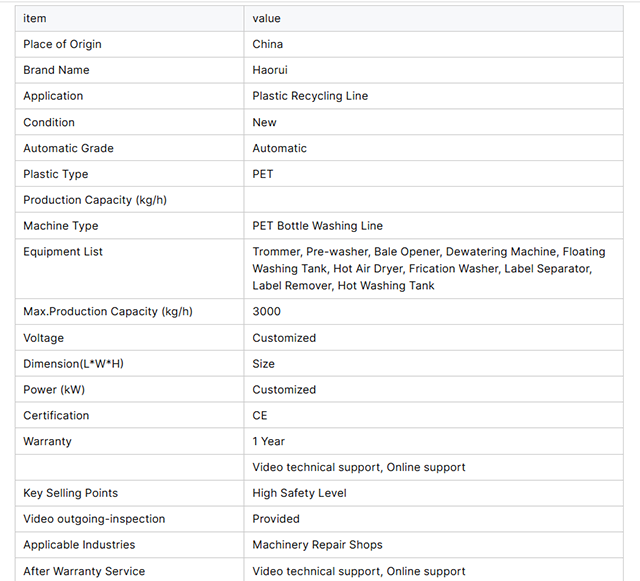

Good Quality Plastic Recycling Machine PET Bottles Label Remover Machine

Product Description:

High Efficiency and Production Capacity: This Haorui label remover machine is designed to process 600-3000 kg of plastic per hour, making it an ideal solution for large-scale plastic recycling operations, as specified by the user.

Automatic and Customized Operation: The remover machine is equipped with automatic grade features and customizable voltage, allowing users to tailor the bottle label remover to their specific needs and ensure a high level of safety and efficiency.

Multi-Functional Design: The PET bottle washing recycling line includes a range of equipment, including a trommer, pre-washer, bale opener, dewatering machine, floating washing tank, hot air dryer, friction washer, label separator, and label remover, providing a comprehensive solution for plastic recycling.

CE Certification and Warranty: The remover machine is CE certified and comes with a 1-year warranty, ensuring that users can operate with confidence and receive support in case of any issues.

Complete Service and Testing: The bottle label remover is accompanied by a machinery test report and video outgoing-inspection, providing users with a thorough understanding of the machine's capabilities and performance, as requested by the user.

Product Function:

1. Separate the PET bottle body from the label paper.

2. The prelude work before crushing of PET production line.

3. To ultimately reduce the PVC content of PET net tablets.

4. Greatly improve work efficiency and replace manual production.

Product Parameters: