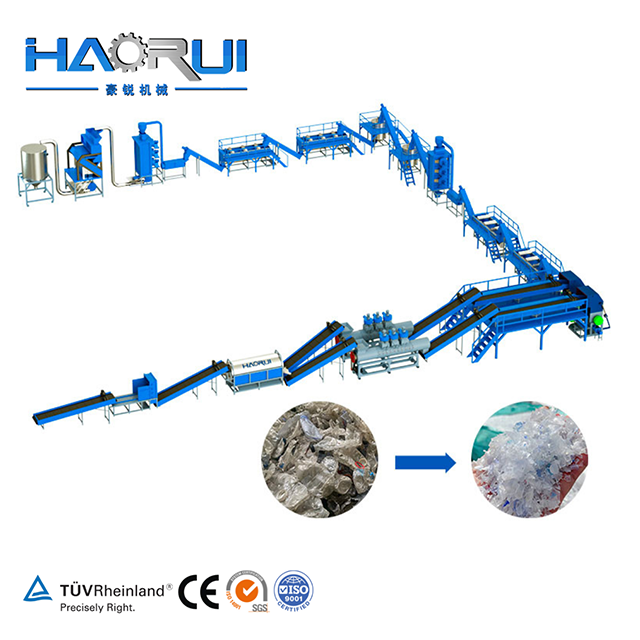

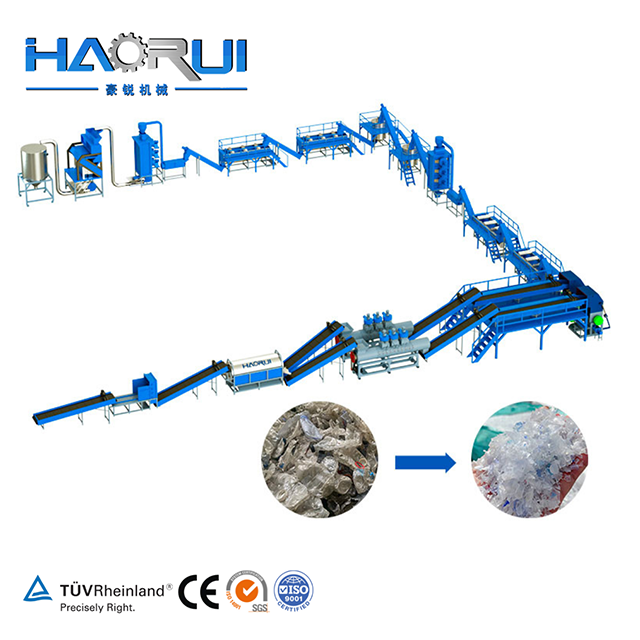

Automatic PET Plastic Bottle Washing Recycling Line for Industrial Use

Product Description:

Efficient Recycling Solution: Our PET sheet & bottle washing line is designed to efficiently crush and clean plastic water bottles, providing a reliable solution for waste plastic recycling lines. This cleaning and recycling line adopts a series of comprehensive equipment, including drum screens, pre washing machines, balers, dehydrators, and flotation machines, effectively improving production capacity and recycling efficiency.

Easy to Operate:The PET bottle recycling machine is easy to operate and designed with user convenience in mind. The complexity of the cleaning and recycling process is minimized to the greatest extent possible, allowing users to focus on other aspects of the business, improve work efficiency, and reduce labor costs. Operators only need to have a simple understanding of the basic operating principles and methods of the equipment to easily handle different recycling tasks.

High Production Capacity:The large-scale recycling of PET plastic bottles is crucial for environmental protection and resource utilization. Our PET bottle washing recycling line has excellent production capacity, capable of processing 1000-1500 kilograms of waste plastic per hour, suitable for large-scale recycling operations and meeting customers' demand for high production capacity. Whether it is cleaning plastic bottles or crushing fragments, this equipment can efficiently complete them, bringing a new solution to the recycling industry.

Comprehensive Equipment List: The comprehensive equipment list includes drum screens, pre washing machines, balers, dehydrators, and flotation machines, each of which plays a critical role. The drum screen is used for preliminary separation of plastic bottles, removing impurities and dirt to ensure effective processing in subsequent stages. The pre washing machine deeply cleans PET plastic bottles to remove residues and stains, improving the reuse rate of plastic bottles. The baler can quickly untangle waste plastic packaging materials, providing convenience for the next step of fragmentation. The dehydrator removes moisture from plastic bottles by high-speed rotation, reducing energy consumption and time costs in subsequent processing stages. The flotation machine uses the principle of buoyancy to separate fragments, allowing materials of different densities to be distinguished and reused.

Comprehensive After-Sales Service: As one of the China’s pet bottle recycling machine manufacturers,Our company provides comprehensive after-sales service to ensure that customers can also receive timely support and maintenance of machines overseas. We are committed to providing our customers with an excellent service experience, including a one-year warranty for our core components.

Pet Bottle Recycling Machine Parameters

Item | Machine | specifications | Unit price FOBtianjin/(USD) | Quantity (set) | Amount (USD) |

1 | Bale breaker | Usage:Break the PET bottle in bale 1.Size:5600mm*1950mm*2700mm 2.Motor:7.5kw 3.Bearing:TR bearing 4.Material:carbon steel

| 6285usd | 1 | 6285usd |

2 | 800 type conveyor belt | Usage:carry and transport plastic materials 1. all frames and supporters are made of carbon steel 2.Width of belt:800mm 3.Length of belt:7000mm 4.The material of belt:rubber 5.Motor power:3kw 6.The thickness of two side plate:3mm 7.Bearing:TR bearing | 1015usd | 1 | 1015usd |

3 | Trommel Screen | Usage:sorting the sand and 1.roller: 1200mm 2.motor: 5.5Kw 3. speed <=30RPM 4.roll material:carbon steel 5.length:4000mm 6.enclosed type:Prevent dust flying | 7142usd | 1 | 7142usd |

4 | 800 type conveyor belt | Usage:carry and transport plastic materials 1. all frames and supporters are made of carbon steel 2.Width of belt:800mm 3.Length of belt:7000mm 4.The material of belt:rubber 5.Motor power:3kw 6.The thickness of two side plate:3mm 7.Bearing:TR bearing | 1015usd | 1 | 1015usd |

5 | 600 type label remover |

Usage:Seperate the label of the PET bottles

1.Moto Power:18.5kw/6 grade 2.Knife material:alloy steel 3.Suction label machine power:.4kw×2sets 4.Shaft length:5500mm 5.Tube Dia:630mm 6.Inner thickness:10mm 7.Label remover power:1.5kw 8.label remover ratio:95% 9.capacity:1000kg/h

| 6585usd | 1 | 6585usd |

6 | 800type sorting platform | Usage:carry and transport plastic material 1. All frames and supporters are made of carbon steel 2. Platform length:6000mm 3. Belt width:800mm 4. Belt material:rubber 5. Motor power:2.2kw 6. Two side plates thickness:3mm 7. Bearing:TR bearing | 1020usd | 1 | 1020usd |

Product Display:

Automatic PET Plastic Bottle Washing Recycling Line for Industrial Use