Fully Automatic 3000kg/h Sheet & Bottle Cleaning System For Plastic Recycling Line

Product Description:

The sheet extruder for pet bottle washing recycling line is composed of extrusion, calendaring, traction and rolling. The main parts of sheet extruder are abrasion resistant, resistant to corrosion and high-temperature resistant by high quality specially-treated. Low resistance force in die head extruding channel makes sheet thickness evenly,.The internal spiral tank in three rollers ensures an effective cooling and it is easy to change and install net changer with the hydraulic pressure unit, no need to stop machine. The machine processes PP/PS granule into PP/PS sheet with single color, which is used for producing plastic products by plastic thermoforming machines, like cups, food container, trays, dishes, bowls, lids, and so on.

Product Features:

Sturdy Construction: This PET Bottle Recycling Machine is built with a sturdy design, weighing 12,000 kg in weight and measuring 15,388 x 3,615 x 2,900 mm in size, ensuring a long-lasting and reliable performance.

Personalized Customization: This sheet & bottle recycling machine can be tailored to meet specific user requirements due to a custom-made voltage system and 150 kW power. Its 1500 rpm screw speed and 35:1 screw l/d ratio enable efficient processing of PP and PS plastics.

Advanced Features: The pet sheet & bottle washing line features a single-screw design, mesh ceramic air-cooled heating, and independent transmission, allowing for precise temperature control and optimized production. It also includes a 5-zone heating system for the T-die and stainless steel heating rods for the screen changer.

Comprehensive Warranty: The sheet & bottle cleaning system comes with a 1-year warranty and a 1-year warranty for core components, including bearings, motors, PLCs, pressure vessels, engines, gearboxes, and screws. Additionally, a machinery test report and video outgoing-inspection are provided for user convenience.

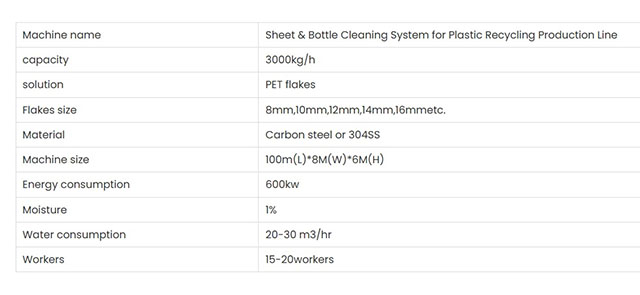

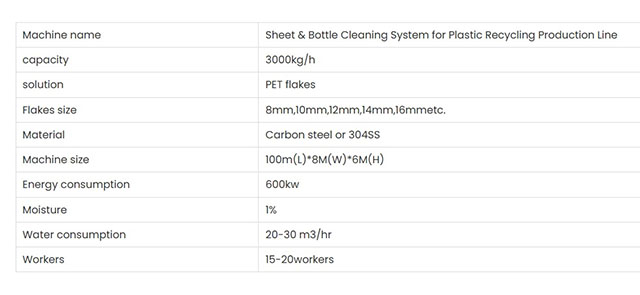

Product Parameters:

Plastic Sheet Recycling Equipment Parameters

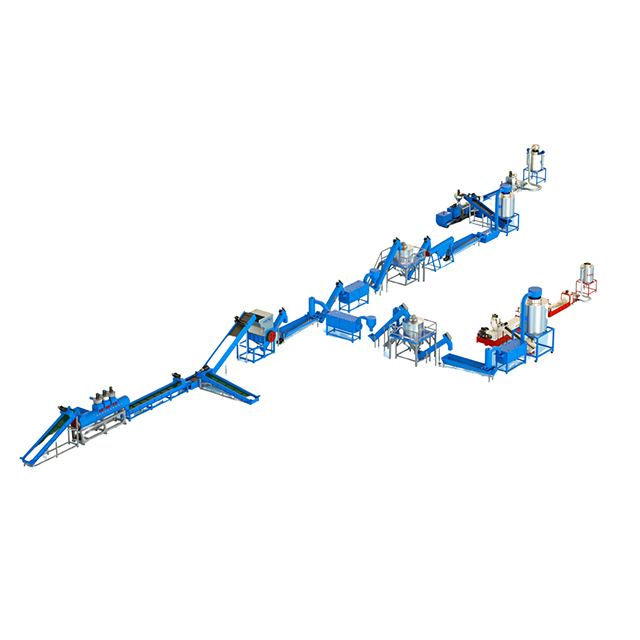

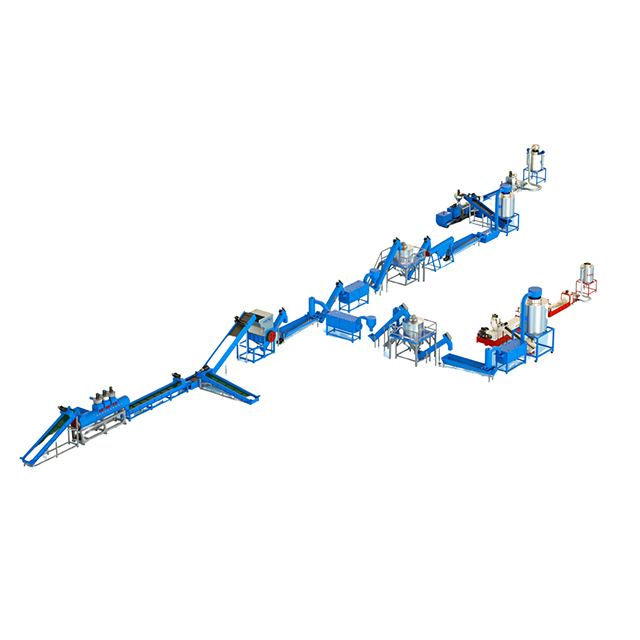

Product Display:

PET Sheet & Bottle Washing Line